Which Statement Concerning Tqm In Services Is False?

Today, we take for granted that the items and services nosotros swallow should work well as presently as we purchase them. In fact, many Industrial and postal service-industrial societies take merely discarded what doesn't piece of work. Nonetheless, there was a time when quality and effectiveness were non always the priority for goods and service providers. The intense focus on quality developed largely after Earth War Ii, in item in the 1980s, in response to a marketplace that rejected inexpensive workmanship and consumer demand increased for durable products that considered the user'due south needs.

In this article, we'll discuss the history of ane of the preeminent quality direction philosophies, total quality management (TQM). Nosotros'll learn how it can assist for profits and nonprofits become more effective and cost-efficient. In add-on, industry experts hash out how TQM compares to other quality philosophies and methodologies, such as Six Sigma and Kaizen.

What Is Full Quality Management?

Total quality management (TQM) describes a direction arrangement wherein a company attains organizational advancement through a commitment to customer requirements. A company meets those requirements when it empowers every employee in every department to maintain loftier standards and strive for continuous comeback. Total quality management is the predecessor of many quality management systems, such as Six Sigma, Lean, and ISO.

See how Smartsheet tin can aid y'all be more constructive

Scout the demo to see how you can more effectively manage your team, projects, and processes with real-fourth dimension work management in Smartsheet.

Watch a free demo

What Is Quality Management?

First, what is quality? It is a mensurate of the level of acceptability of a product or service. The ASQ Quality Glossary defines quality direction every bit "the application of a quality management organization in managing a process to achieve maximum client satisfaction at the lowest overall cost to the system while continuing to improve the procedure." Quality management has 4 parts: quality planning, quality assurance (defect prevention), quality control (which includes product inspection and other elements, such equally competence), and quality comeback.

Why would information technology accept until the 20th century to apply such seemingly obvious principles like product goals and parts inspection? Maybe the correct historical circumstances didn't present themselves until the 20th century. Nichols credits new mass-product techniques, such every bit Ford's assembly line, and the urgent demand for materials during two globe wars for this particular innovation. "The U.s.a. military demanded to some extent that every product they purchased be expert because soldiers lives literally depended on the quality of the products they handled," says Nichols. "Whether it was for K rations or bullets, these wars spurred a manufacturing revolution to focus on the idea of getting things correct every time."

Statistics play an integral role in quality management because existence able to predict accuracy through numbers is much less expensive than inspecting parts. Moreover, sometimes inspection is just inconvenient. "McDonald's needs to know that every burger is correct without having to take a bite out of each one," says Nichols.

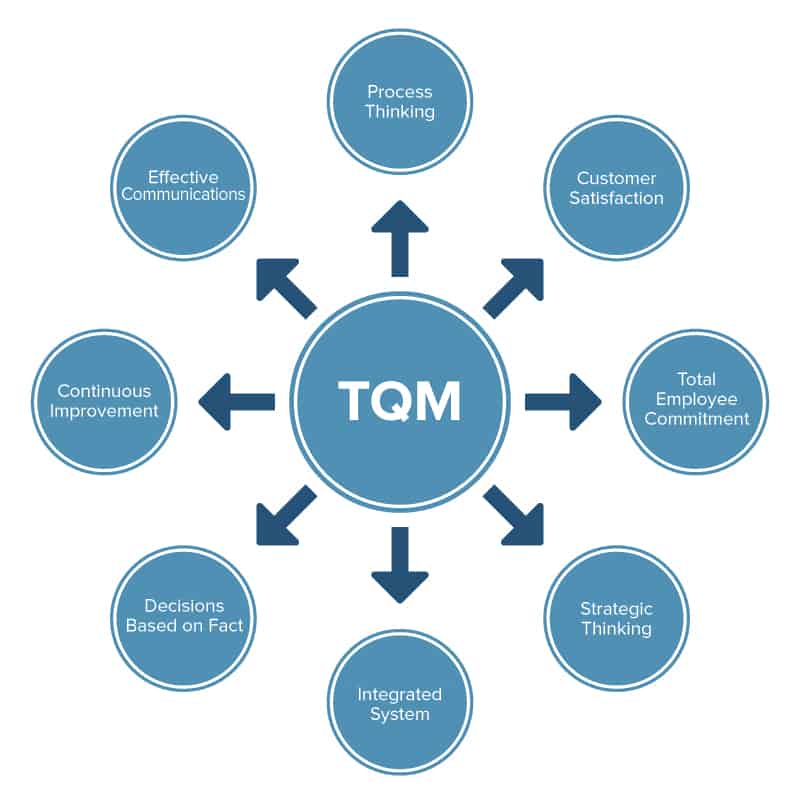

Total Quality Management Principles

No unmarried accustomed torso of knowledge exists for total quality management, as does, for instance, the Project Management Body of Knowledge (PMBOK) for the Project Management Constitute. Similarly, no prescribed deportment be for implementing TQM methods and tools. Organizations have been free to deploy and adapt TQM every bit they run into fit, giving fashion to many definitions of the methodology. Despite these challenges to standardization, it's possible to describe generally accepted principles:

- Customer Satisfaction

- Employee Commitment: This creates empowerment through training and suggestion mechanisms.

- Fact-Based Determination Making: Teams collect data and process statistics to ensure that piece of work meets specifications.

- Effective Communications: There should exist an open up dialogue throughout an organization.

- Strategic Thinking: Quality must exist part of an system'due south long-term vision.

- Integrated System: A shared vision, including knowledge of and delivery to principles of quality, keep everyone in a company connected. Taiichi Ohno recognized that even suppliers are an important function of the system.

- Process-Centered: Yous can deconstruct every activity into processes, and, therefore, locate and repeat the best procedure.

- Continuous Improvement: Every employee should always exist thinking nearly how to better perform their task.

You could sum up the goal of TQM in this way: "Exercise things right the offset time, every time."

The History of Total Quality Management

At that place is no unmarried, agreed-upon source for the phrase total quality management. Some experts believe it came from two books by seminal quality management thinkers: Armand Feigenbaum'due south Total Quality Control and Kaoru Ishikawa'due south What Is Total Quality Control? The Japanese Way. Others say the terminology arose from an initiative in the Us Navy to adopt quality management guru William Deming's recommendations, which they termed full quality direction. TQM did not enjoy widespread acceptance until the 1980s.

The roots of the principles and practise of TQM extend back to the early 20th century and Frederick Taylor's Principles of Scientific Management, which advocated a consistent way of performing tasks and inspecting finished work to foreclose defective products from leaving the store. Further innovation came in the 1920s with Walter Shewhart's elaboration of statistical process controls, which 1 could use at any indicate in the production process to predict quality levels. Information technology was Shewhart who developed the control nautical chart, used today for managing with Kanban and Agile.

Throughout the 20s and 30s, Shewhart's friend and mentee, William Deming, adult statistical process control theories that he would eventually use to assist the US Census department in the early 1940s. This was the offset apply of statistical process control in a non-manufacturing field.

The Outset of the Quality Era in Nihon

Afterward the war, other American quality theorists, including Deming, who would achieve hero status in Japan, advised Japanese industry on how to improve processes and output to rebuild their state of war-shattered economy. At the fourth dimension, the term fabricated in Japan was synonymous with shoddy adroitness. As early equally 1945, such visionaries as electrical engineer Homer Sarasohn spoke about decision-making variation and monitoring process to produce better deliverables.

As a result, in the 1950s, quality became the byword for Japanese manufacturing. Quality concerned non just management, but all levels of a company. In the 1960s, quality circles began appearing in Japanese workplaces to allow employees the opportunity to talk over problems and consider solutions, which they so presented to management. Starting on the factory floor, quality circles spread to other functional departments. The company-wide focus on quality may also provide a clue to the origin of the phrase total quality.

Total Quality Direction in the USA

By the 1970s, the term fabricated in the USA was no longer a badge of pride. Since the terminate of WWII, the main effort in American factories was to produce a large quantity of items, maintain the production schedule, and salvage money. Usability and durability seldom mattered until concerns about lack of product quality reached a fever pitch. As Japan successfully challenged the Us for industrial leadership, US manufacture now took a folio from Japan'due south quality-improvement book. A new interest in quality direction took concord, building on the work of Shewhart's disciples, such as Deming, Josef Juran, and Kaoru Ishikawa in Nippon. Influential businessmen like Philip Crosby championed the trend.

Although the growth of TQM seems to have occurred exclusively within the precincts of industry, the basic outlines of the concept owe much to a 1980s US Navy project that used Shewhart and Deming'southward PDCA (plan, do, check, deed) model. Navy guidelines articulated the principles that customer requirements should ascertain quality and continuous improvement should pervade an entire organization. Navy success with the methodology led to TQM's adoption by other armed forces, such as the army and coast guard, and eventually the rest of the United states of america government. Congress established the Federal Quality Establish in 1988 to highlight the demand for quality management in business and reward organizations for successful implementations.

Total Quality Management Meets the World

Quality management began in manufacturing, and TQM, like it's subsequent methodologies, adapted well to finance, healthcare, and other fields. Some of the landmark companies to adopt TQM include Toyota, Ford, and Philips Semiconductors.

Worldwide, countries such as Germany, French republic, the United kingdom of great britain and northern ireland, and Turkey established TQM standards. But by the 1990s, TQM was superseded by ISO (International Standards Arrangement), which became the standard for much of continental Europe, and by another methodological response of the 1980s to quality concerns, Half dozen Sigma. Nevertheless, TQM principles form the basis for much of ISO and Six Sigma. For example, PDCA appears under the Six Sigma method DMAIC (define, measure, analyze, meliorate, control). And in the 2000s, the ISO governing body recognized TQM as a foundational philosophy. TQM lives on in data-driven methods for a data-driven age.

William Deming and the Origin of Total Quality Management

Much of our current agreement of the value and pursuit of quality traces dorsum to William Deming. This American statistician, engineer, and management consultant laid many foundations for the use of statistics in production and work management. He introduced statistical process methods to the U.s. Census Bureau in the early on 1940s, marking the commencement time they were used in the business or service sector. During WWII, he advised United states business concern and government on statistical methods to help with planning for wartime manufacturing. After the war, Deming was recruited by no less than General Douglas MacArthur to suggest Japanese officials on census models to assess state of war damage and program for rebuilding.

Deming distinguished himself among many of the occupying forces past showing a genuine interest in Nihon and its culture. Perhaps it's non surprising, then, that the Japanese revere him for his role in midwifing the Japanese economic miracle.

Because Nippon lacked abundant natural resource, Japanese leaders viewed the exportation of appurtenances worldwide as their main path to financial success. Their postal service-war reputation for low-quality products posed a detail challenge to this goal. Deming was invited back to Japan by the Union of Japanese Scientists and Engineers (JUSE), whose president was Kaoru Ishikawa, to discuss quality management, ideas that formed the ground for what later became known as TQM. Japanese products were gradually recognized for usability and durability. In 1960, for his efforts on behalf of Japanese manufacture, Deming received the 2d Order Medal of the Sacred Treasure from the Emperor of Japan. By the 1970s, Japanese exports surpassed those of the U.s..

By contrast, American goods gained a reputation for poor pattern and defects. As early every bit 1940, Juran remarked that producing goods and meeting deadlines took priority, with quality being relegated to the concluding inspection. Deming believed that as shortly as the war was over, US industry lost involvement in statistical methods for pursuing quality. Ironically, information technology was Deming who, in the late 70s and early 80s, introduced the Us and the UK to the quality management principles he'd taught in Nippon 30 years earlier. In 1967, he published the article "What Happened In Japan?" in the journal Industrial Quality Control. Professionals consider information technology to be an early version of his famous xiv Points and PDCA cycle.

Although well-known in academic quality control circles, he accomplished greater prominence when he was interviewed for the 1980 NBC documentary "If Japan Can, Why Can't We?" In the program, Deming emphasized that, "If y'all get gains in productivity, information technology is only because people piece of work smarter, not harder. That is total profit, and it multiplies several times." The documentary revealed another act in Deming's life, that of a sought-after quality consultant to American concern. He gained a reputation for bluntness and fearlessness in the presence of senior executives. Fable has information technology he told senior Ford staff that 85 percent of quality bug resulted from poor management decisions. Some companies rejected him. However, on his advice, Ford conducted user surveys before designing and building the Ford Taurus. In 1992, the Taurus became the number one selling machine in the United states of america.

In his 1986 book, Out of the Crisis, he discussed his 14 Points for Management. The following year, at the age of 87, he was awarded the National Medal of Technology. In 1993, the year of his decease, he established the Deming Constitute.

Why Is Total Quality Direction Important to an Organization?

Nichols says that TQM tools and principles acquire power not when an system creates a defended quality department, but when it includes the whole company in the pursuit of high quality. An instance is the quality circumvolve, in which workers directly involved in a procedure brainstorm to detect solutions. "People are a fabled resources that is frequently underutilized. The leadership frequently doesn't recognize the value that they bring to the everyday workplace. Employees know how to prepare issues," asserts Nichols. In add-on to tapping a native resource, implementing a TQM philosophy can assist an organization:

- Ensure customer satisfaction and customer loyalty

- Ensure increased revenues and college productivity

- Reduce waste matter and inventory

- Better design

- Conform to changing markets and regulatory environments

- Increase productivity

- Heighten market paradigm

- Eliminate defects and waste

- Increase job security

- Improve employee morale

- Reduce costs

- Increase profitability

What Are the Costs of Quality?

A fundamental tenet of TQM is that the toll of doing things right the get-go time is far less than the potential cost of re-doing things. There are also residuum losses when customers carelessness products and brands for quality reasons. Some schools of thought view quality as having a cost which cannot be recouped. Juran, Deming, and Feigenbaum held a different view. For advocates of TQM, the toll of quality really describes the cost of not creating a quality deliverable. In that location are four primary price categories:

- Appraisal Costs: Appraisement costs cover inspection and testing throughout the production cycle. This includes verifying that the materials received from the supplier run into specifications and ensuring that products are acceptable at each stage of production.

- Prevention Costs: Prevention costs include proper setup of piece of work areas for efficiency and safety, and proper grooming and planning. This type of cost also includes conducting reviews. Prevention-related activities frequently receive the smallest allotment of a company's budget.

- External Failure Costs: This category concerns the cost of problems post-obit a production's market release. They may include warranty issues, product recalls, returns, and repairs.

- Internal Failure Costs: Internal failures are the costs of problems before products reach customers. Examples of internal failures include cleaved machines, which cause delay and downtime, poor materials, scrapped product runs, and designs that crave rework.

Total Quality Management Models

Although TQM does non possess 1 universally recognized body of noesis, organizations do pattern their efforts after a few formal models, including several industry entities and awards.

The Deming Application Prize was created in Japan in 1950 by the Spousal relationship of Japanese Scientists and Engineers (JUSE) to acknowledge companies and individuals from around the world for their successful efforts at implementing TQM. Winners have included Ricoh, Toyota, Bridgestone Tire, and many others.

Congress established The Malcolm Baldrige National Quality Award (MBNQA) in 1987 to raise awareness of quality and reward United states of america companies who pursue it. The National Constitute of Standards and Technology (NIST) administers the honour. It is given to large and small companies and nonprofit entities that demonstrate excellent functioning in the following areas:

- Delivery of increasing value to customers and stakeholders, contributing to organizational sustainability

- Improvement of overall organizational effectiveness and capabilities

- Implementation of organizational and personal learning

Past winners take included the Chugach School District, Concordia Publishing Business firm, and Boeing Mobility.

The nonprofit European Foundation for Quality Management (EFQM) was established in 1989 to provide a quality framework for organizations throughout Europe. They maintain the EFQM excellence model, which embraces the following precepts:

- Adding value for customers

- Creating a sustainable future

- Developing organizational capability

- Harnessing inventiveness and innovation

- Leading with vision, inspiration, and integrity

- Managing with agility

- Succeeding through the talent of people

- Sustaining outstanding results

Participating organizations can partake of grooming and cess tools and may apply for the EFQM Excellence Award.

The International Organisation for Standards (ISO 9000) publishes guidelines and specifications for parts, processes, and even documentation to ensure that quality is consistent beyond companies, organizations, and borders.

How Do You lot Implement Full Quality Management?

PDCA lies at the core of many 20th century quality efforts. PDCA began in the 1920s equally a conception by engineer and statistician Walter Shewhart. It was originally chosen PDSA (plan, practice, report, human activity). Widely disseminated past Deming, who referred to it as the Shewhart bicycle, it is now often referred to as the Deming cycle.

"Plan: The planning phase is the most important. That's where management, along with the associates, identify the problems to encounter what really needs to be addressed — the day-to-day things that may be happening on the productivity side that management is not enlightened of. So they're trying to decide a root cause. Sometimes, employees practise research or high-level tracking to narrow downward where an issue may originate.

Exercise:The doing stage is the solution phase. Strategies are adult to try to fix those issues identified in the planning phase. Employees may implement solutions and if a solution doesn't announced to work, it'due south back to the drawing board. In contrast to Six Sigma, it's less about measuring gains and more almost whether the employees judge the solution to exist working.

Check:The checking phase is the before and after. So after you've made these changes, you see how they're doing.

Act:The acting phase is the presentation or the documentation of the results to let everybody know, 'Hey, here's how we were doing it. Here's how information technology is now. This is the new way, and this is what this should address going forrard.'"

Nichols says that in 2000, ISO best-selling PDCA as a foundational method. Information technology appears once again in Six Sigma as the DMAIC method (define, measure, clarify, improve, and control). Walters notes that TQM is much more people oriented, while Six Sigma is process based. He sees, for example, that the term ascertain "takes the human being chemical element out" and the term measure focuses on data.

Total Quality Management, Kaizen, and Six Sigma: Which One When?

While TQM'south method of using employees every bit a source of ideas and solutions tin help companies, Six Sigma'due south process and measurement focus — which promotes data-driven decisions — offers compelling benefits. Walters uses the example of producing peanut butter and jelly sandwiches.

"Nosotros'd start out with two pieces of breadstuff, add the peanut butter, add the jelly, and put the 2 pieces of bread together. Simply, possibly the edges are smashed together. Maybe the corners are damaged. Or, when our customers get it, they say the breadstuff is soggy. Inside that process, we're not sure whether we're putting on also much jelly or whether nosotros're using the wrong type of peanut butter. You lot simply don't know what it is, and so you lot have these group meetings and brainstorm until your customer response is what you lot desire, and the level of acceptance of your quote unquote quality product is where you desire it to be," says Walters.

With Six Sigma, still, the questioning process would drill downwards to the details. What kind of bread were yous using? What kind of peanut butter? What kind of jelly?

"That to me is the do good because it takes the onus off the people and focuses strictly on the procedure," asserts Walters. "So, if we tighten upwardly the process, nosotros can feel like we already have quality people. And after the procedure is repeating in the aforementioned manner, even if at that place are other performance issues, that automatically sets you lot back to the human being side. Simply then you can manage the human issue properly because you don't take to worry about your processes. Your numbers aren't changing."

Walters states further that well-nigh companies want to develop brand loyalty, even if their product is essentially the aforementioned as a competitor'due south. "If nosotros employ TQM, we hope a product is of better quality, so you'll come back. With TQM, y'all have to wait for your customers to confirm that it'southward good. With Half dozen Sigma, at the cease of the day, you don't guess if your product is better. You lot know it. If you properly identify your market place and your production has the best fit for the niche, you know you have the all-time product from a procedure perspective. That leads to the deeper relationships," he says.

If Six Sigma can offer definitive results for an existing process and TQM tin can help achieve results over time, where does Kaizen fit? Kaizen is a Japanese word meaning philosophy of improvement. Information technology includes the 5 Ss, seiri, seiton, seiso, Seiketsu, and shitsuke, translated loosely into English as sort, set in order, shine, standardize, and sustain. Kaizen is considered more of a philosophy for how to organize your workspace and the larger workplace and how to take the right mental attitude toward your work and coworkers.

Kaizen events are improvement efforts that involve small teams that spend a short time, usually well-nigh a week, considering and testing improvements. The team then presents its findings to direction. Management periodically reviews the solutions to make sure that they continue to benefit the squad.

Similar TQM, Kaizen approaches efforts from the perspective that the whole company is responsible for quality and that improvement must be continuous. It is generally less methodological than Six Sigma, although Kaizen may inform the lean attribute of Lean Six Sigma.

The 7 Basic Tools of Total Quality Direction

According to the experts, the basic tools of TQM let anyone - even someone without statistical training - to get together data to illuminate well-nigh bug and reveal possible solutions. Here are the seven basic tools of TQM:

- Check Sheet: This is a pre-made form for gathering one blazon of information over time, so it's only useful for frequently recurring data.

- Pareto Chart: The nautical chart posits that 80 percent of problems are linked to twenty percent of causes. It helps you lot identify which problems fall into which categories.

- Cause and Outcome Diagram or Ishikawa Diagram: This diagram allows you to visualize all possible causes of a problem or outcome then categorize them.

- Control Chart: This chart is a graphical description of how processes and results change over time.

- Histogram Bar Nautical chart: This shows the frequency of a problem'southward cause, too as how and where results cluster.

- Scatter Diagram: This diagram plots data on the x and y axes to make up one's mind how results alter as the variables alter.

- Flow Chart or Stratification Diagram: This represents how different factors bring together in a procedure.

The Central Players in Total Quality Direction: Customers, Suppliers, and Employees

To accomplish success with a total quality direction plan or any other improvement methodology, managers must understand the quality goals for their product or visitor. They must then communicate those goals, in improver to the benefits of TQM, to the visitor, every bit employees play a vital function by contributing their intimate, day-to-day knowledge of production creation and processes.

TQM is a philosophy that values comprehensiveness. Therefore, suppliers are a crucial office of TQM execution. Companies must vet new suppliers and regularly inspect existing suppliers to guarantee that materials meet standards. Communication with suppliers most TQM goals is too essential.

Customers are the nigh significant part of the TQM equation. After all, they're the reason for TQM'due south existence. Bated from the obvious feedback the sales team provides, customers — production or service users — give information near what they desire from the deliverable, whether that deliverable is tangible or a service.

Certifications in Total Quality Management

Since its heyday in the 1980s and 1990s, TQM has been largely superseded by Six Sigma and ISO 9000. "The thing about Lean and Six Sigma is that they accept a very definite set up of methods to achieve these goals effectively. You become do x, y, and z," explains Nichols. "ISO is a universal standard, and it'due south articulate what you accept to exercise.Of course, what goes along with that is that you tin can be certified, which is outside the scope or remit of TQM," concludes Nichols. He suggests that TQM lost traction in the UK because Europe adopted ISO in the 1990s. Today, formal TQM training is rare. Nichols suggests that companies with interest in pure TQM may pursue something like the Baldrige award.

Delivering Quality with Improved Processes in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to lucifer the needs of your team — and adapt every bit those needs alter.

The Smartsheet platform makes information technology easy to program, capture, manage, and study on piece of work from anywhere, helping your squad exist more effective and become more done. Written report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to go on your team connected and informed.

When teams have clarity into the work getting done, there's no telling how much more than they can achieve in the same amount of fourth dimension. Try Smartsheet for gratuitous, today.

Source: https://www.smartsheet.com/total-quality-management

Posted by: camachocamse1999.blogspot.com

0 Response to "Which Statement Concerning Tqm In Services Is False?"

Post a Comment